> Home > Products

Info:

Applications:

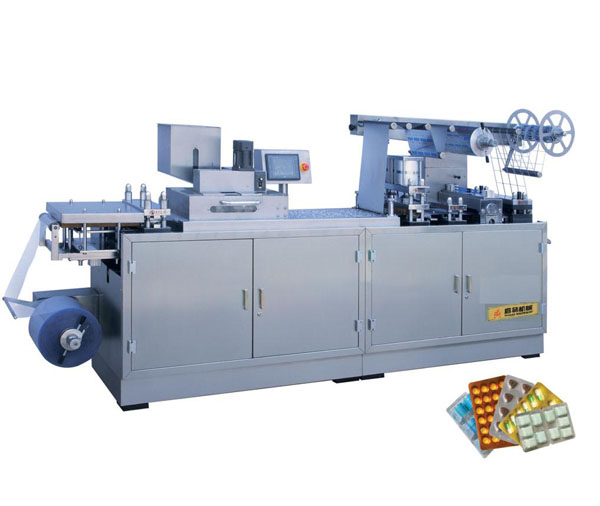

1.Travel scope can be adjusted.Mould is located by located groove so that it's easy to change mould,The machine heats the PVC through conduction and forms it through pressing and frothing.

2.Speed is shifted by stepless transducer.Adopt the interface of human-machine and PLC rogrammable controller.Adopt professional feeder and feed accurately.

3.The equipment of trace pressing,batch number printing and scrap-collecting can be chose.

4.Double stepping motor drive wheel to grip and tow wrapper,synchroning accurately.

5.The heating moulds will automatically separate when the machine stops,which contributes to protect the material between them and extend the machine's life..

Main technical data:

Model

320A

260A

160A

Blanking frequency(times/min)

15-50

15-50

15-50

Sheet's quantity of one blanking(sheets)

5-6

3-4

1-2

Adjustable scope of feed travel(mm)

5400-18000

3600-12000

1800-6000

Appropriate for Capsule

10-150

10-140

10-130

Max Forming area and depth(mm)

320×130×13

250×120×13

140×110×13

Capacity of air compressor((m3/min) )

≥0.45

≥0.38

≥0.36

Power supply

380V 50HZ 12KW

380V 50Hz8.5KW

380V 50Hz 635KW

Wrapper specification(mm)

PVC

320×(0.2-0.5)

260×(0.2-0.5)

140×(0.2-0.5)

Aluminum foil

320×(0.02-0.035)

250×(0.02-0.035)

140×(0.02-0.035)

Overall dimensions(mm)

3800×718×1750

3200×650×1450

2850×530×1450

Part size(mm)

2000×718×1750

1750×650×1450

1450×550×1300

1800×718×1750

1450×650×1450

1400×550×1450

Weight(Kg)

2000

1700

1000